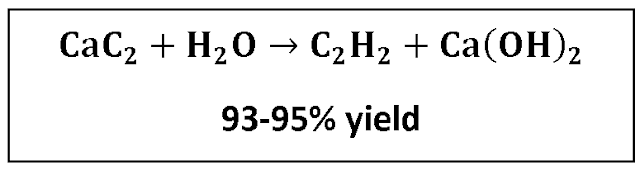

ACETYLENE INDUSTRIAL MANUFACTURING PROCESS

Reaction

RAW MATERIAL REQUIREMENT TO MAKE 1 METRIC TON OF ACETYLENE

Calcium Carbide (85%) : 3490 kg

Water :

28,825 kg

Calcium Carbide is formed when Lime

(essentially free of phosphates and Magnesium Carbonate) and Coke (with low ash

content), mixed in a ratio of 60:40 are heated to a temperature of 2000 to 2100

degree C in an electric furnace. The Carbon Monoxide may be recovered and used

as a fuel in lime kilns or as a raw material for chemical synthesis. The liquid

Calcium Carbide is allowed to cool and solidify for 24 to 48 hours and is then

crushed and screened for size. The grinding operation are carried out in an

atmosphere of Nitrogen to prevent explosion from Acetylene Generated by

moisture in the air. The approximate requirements per metric ton of Carbide

are:

Lime – 991 kg, Coke – 683 kg, Electrode

Paste – 17 to 20 kg, Electricity – 3200 kWh, and labor – 5 man hours.

The Carbide so produced is about 80%

Calcium Carbide; 1 kg of Carbide yields about 0.29 cubic meter of Acetylene.

These are two standard methods for the

production of Acetylene from Calcium Carbide and water: the wet process and the

dry process. The wet process consists of adding the carbide to a relatively

large quantity of water, releasing Acetylene gas while the calcium Hydrate

residue is discharged in the form of a Lime slurry containing approximately 90%

water.

In order to eliminate the waste of

Calcium Hydrate, the dry process was originated in which a limited amount of

water (1:1 by weight) is added to Calcium Carbide in a generator. The heat of

reaction (1475 kcal/cubic meter) Acetylene generated) is employed to vaporized

the excess water over the chemical equivalent, leaving a substantially dry

Calcium Hydrate suitable for reuse as a Lime source. The temperature must be

carefully controlled, since Acetylene Polymerized to from Benzene at 600 degree

C and violently decomposes at 780 degree C, and Air mixtures may explode at 480

degree C. Generators of both types are usually designed to operate below 150

degree C and 15 psi (100 kPa).

The crude gas (containing traces of

Hydrogen Sulfide, Ammonia, and Phosphine) from the generator is either scrubbed

with water and Caustic Soda solution or Led to purifier where the impurities

are absorbed by the use of Iron oxide or active Chlorine compounds. The dry gas

is fed to cylinders to manufacturing units.

PROPERTIES

Colorless, Flammable gas, odorless when

pure but ordinarily has a Garlic like order because of impurities.

Molecular Weight : 26.04

Specific Gravity : 0.618, 20

degree C/4

Freezing Point : -80.8 degree C

Boiling Point : -84 degree C

Flash Point (open cup) : Gas

Ignition Temperature : 644 degree C

Vapor Density (air = 1) : 0.91

Explosive Limits % by volume in air : Lower 2.5 and Upper 82

Threshold Limit value in ppm : 1000

One pound of Acetylene is equivalent to 14.5 cubic ft (1 kg

= 0.9 cubic meter). Soluble in Acetone (2500 ml gas/100 g, 3000 ml gas/100 g at

12 atm), ethanol (600 ml/100 g), water (100 ml/100 g), and liquid a

Ammonia at room temperature.

Containers &

Regulations – Steel pressure cylinder containing

from 60 to 300 cubic ft of Acetylene (1.7 to 8.5 cubic meter). Mixtures of Air

and acetylene, as well as liquid Acetylene are highly explosive. The cylinder

must therefore contain a suitable solvent (such as Acetone) and generally a

porous material (such as Asbestos, kapok, or diatomaceous earth) on which the

solution is impregnated. The cylinder pressure must not exceed 250 psi (1.7

MPa) at 21 degree C, and requires a Red DOT shipping

label.

ECONOMIC ASPECTS

Acetylene is produced on the post where

needed by means of portable generators utilizing Calcium Carbide.

Economic Ascepts

Acetylene, Once used primarily in the

metal industry for cutting and welding, is now used chiefly in the manufacture

of chemicals. In this field economics problems of Acetylene manufacturer and

use are of dual nature: whether to use Acetylene at all in a given process and,

if so, whether to make it from Calcium Carbide or from Hydrocarbon gases.

The major chemicals presently

manufactured, at last in part, from acetylene are Vinyl Chloride monomer, Vinyl

Acetate, Acrylates, and tri and perchloroethylenes. Many of these can be made

alternatively from ethylene and other petroleum hydrocarbons, so ultimate costs

by the two routes becomes an important factor. Currently, ethylene is favored

for vinyl acetate and chloride; propylene is preferred for the manufacture of

Acrylates. Manufacturing routes to Acetaldehyde, Acetic acid, and

Acrylonitrile, formerly held by acetylene, have been taken over by Ethylene and

Propylene.

Increased use of Acetylene has developed through

Rappe chemicals. Some of these are propargyl Alcohol, Butyrolactone, Vinyl

pyrrolidone, Polyvinylpyrrolidone, 1,4 – butanediol, 2 – butyne – 1,4 – diol,

and Tetrahydrofuran.

Comments

Post a Comment

If you have any doubts, please let me know